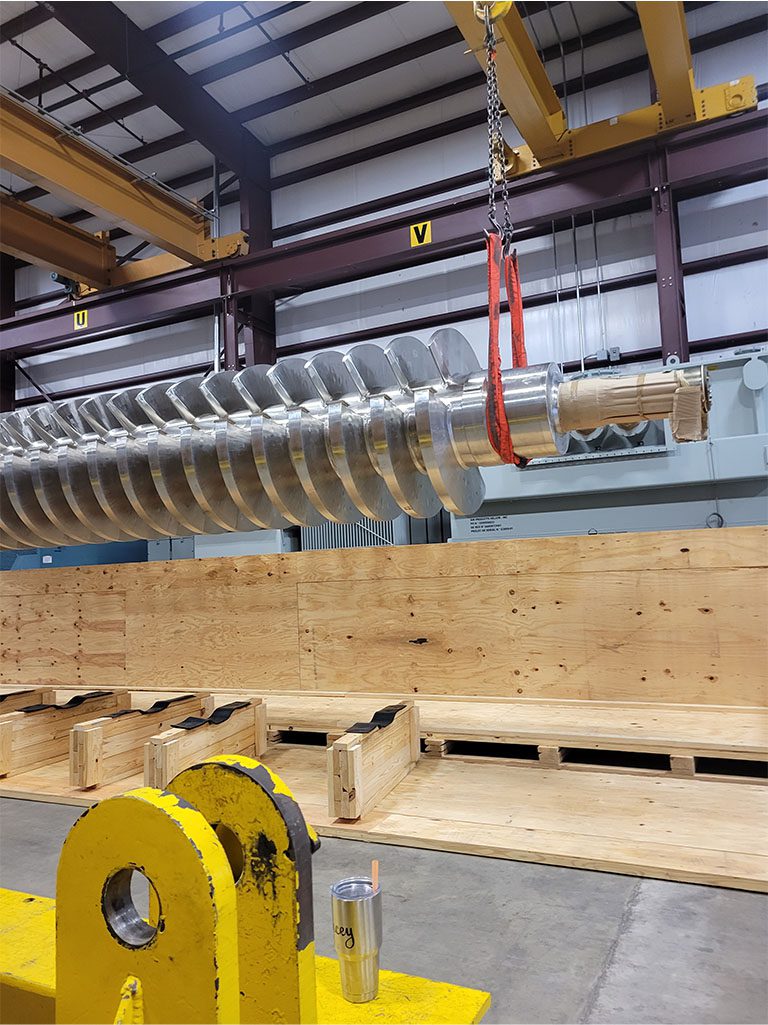

Ensuring Safe Transport for Multi-Ton Heater Shafts

In the modern industrial landscape, the safe and secure transportation of heavy equipment is a crucial service. When our organization teamed up with a moving industry leader to provide crating services for one of the world’s largest chemical companies, we faced the formidable task of crating two 40-foot-long, multi-ton heater shafts. These shafts, integral to the development of electrically heated steam cracker furnaces used in the petrochemical industry, needed careful handling and transport from Texas to Germany.